You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

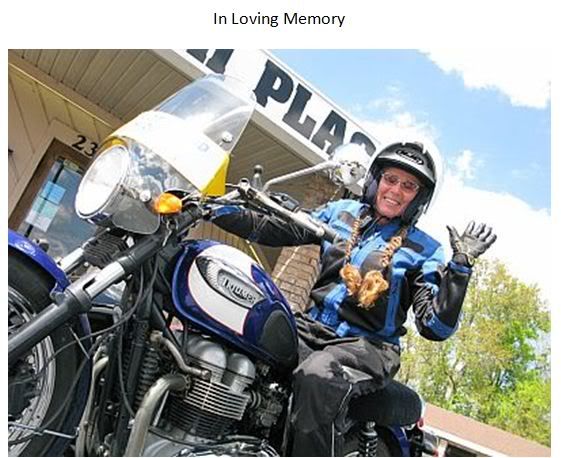

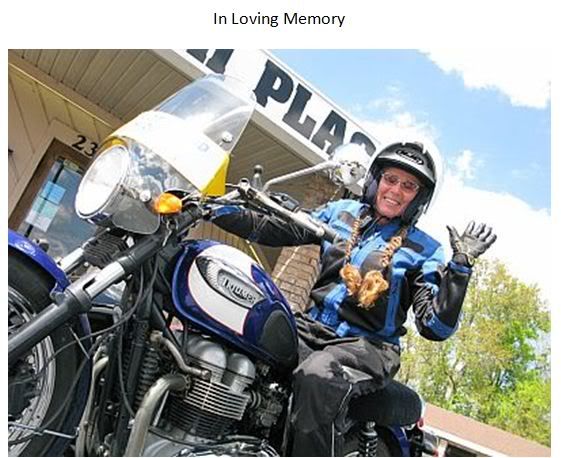

Wayne's Triumph Trident 750 engine overhaul by GrandPaul

- Thread starter grandpaul

- Start date

Help Support Triumph Motorcycle Forum:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

There are several very good restoration threads here. GrandPaul is our resident expert. He restores/rebuilds bikes of all brands for a living. He did a beautiful job on my 1968 Trophy basket case.

Carl, that composite photo is still one of my most impressive to-date. Maybe only challenged by that scruffy Oklahoma red dirt Norton chopper turned into a cafe racer...

Paul, you did masterful work on both of them! Jobs very well done. That has got to be source of pleasure and pride for you. It surely is for me and I didn't do the work!

What info were you looking for?

What method for dismantle driver side cover ( with a ball bearing ) did you use ?

What rings and clearances did you use ( I assume the original pistons were still within tolerances ) ?

Did it work ? ( I mean no smoking and oil consumption after the owner started using a bike ? )

Was a deck of cylinder flat, or individual cylinders were protruding a little bit ?

If yes, how much ?

Did you check bases for a clutch and clutch sprocket are concentric to the mainshaft base ?

What kind of gasket did you use for rocker box and covers ?

Did your choice of gaskets work ?

From the top of my head .

.

What rings and clearances did you use ( I assume the original pistons were still within tolerances ) ?

Did it work ? ( I mean no smoking and oil consumption after the owner started using a bike ? )

Was a deck of cylinder flat, or individual cylinders were protruding a little bit ?

If yes, how much ?

Did you check bases for a clutch and clutch sprocket are concentric to the mainshaft base ?

What kind of gasket did you use for rocker box and covers ?

Did your choice of gaskets work ?

From the top of my head

The head & cylinders had already been done by the client, as well as pistons & rings.

All tolerances measured within spec and everything went together nice and smooth.

It's NOTHING like a 500 plus a cylinder; NOT EVEN CLOSE.

All tolerances measured within spec and everything went together nice and smooth.

It's NOTHING like a 500 plus a cylinder; NOT EVEN CLOSE.

Not to worry, as long as you have readily available parts book & shop manual, plus a few specialty tools for pinion pulling, etc..

Thanks Grandpaul,

I am stripping down a 1971 t150 as I type this note. The bike was given up for dead thirty years ago after a rebuild due to an excessively tight crankshaft/camshaft.

Hopefully I can find out what is causing the problem. Your detailed high resoltion photos are invaluable.

BTW, the restoration 30 years back by a long since closed motorcycle shop in the bay area (CA) had included welding a hole in the right crankcase cover caused a by errant conecting rod. In your experience, would the welding repair of the right case cover be a likly cause of the very tight crankshaft?

Any thouhts would ge greatly appreciated.

Regards,

Pat

I am stripping down a 1971 t150 as I type this note. The bike was given up for dead thirty years ago after a rebuild due to an excessively tight crankshaft/camshaft.

Hopefully I can find out what is causing the problem. Your detailed high resoltion photos are invaluable.

BTW, the restoration 30 years back by a long since closed motorcycle shop in the bay area (CA) had included welding a hole in the right crankcase cover caused a by errant conecting rod. In your experience, would the welding repair of the right case cover be a likly cause of the very tight crankshaft?

Any thouhts would ge greatly appreciated.

Regards,

Pat

It is entirely possible that the welding repair did not result in close enough alignment, and could indeed be the cause of restricted rotation.

As soon as you pull the top end off, including the pistons off the rods, and the intermediate timing pinion, you should be able to easily rotate the crankshaft by hand with nearly zero perceptible restriction.

Glad my photos are helpful, that's the exact intention.

As soon as you pull the top end off, including the pistons off the rods, and the intermediate timing pinion, you should be able to easily rotate the crankshaft by hand with nearly zero perceptible restriction.

Glad my photos are helpful, that's the exact intention.

Hi Grandpaul,

Followed your suggestion regarding the lower end, the crank and intake cam turned smoothly, like butter. However, exhaust cam is very tight, will turn, but not by hand. I reversed the cams, put the intake caminto exhaust side, same thing very tight, and the exhaust cam turned smoothly on the intake side.

The verdict: probably a warped timing side case. BTW, the cases and main caps all have the same 4 digit number.

What do you recommend? Is line-boring the cams bearings on a t-150 big job, and can any machine shop do it?

Thanks Grandpaul, I appreciate you sharing your knowledge and experience.

PS- this list seems much less trafficed than a few years ago. Is that my imagination?

Followed your suggestion regarding the lower end, the crank and intake cam turned smoothly, like butter. However, exhaust cam is very tight, will turn, but not by hand. I reversed the cams, put the intake caminto exhaust side, same thing very tight, and the exhaust cam turned smoothly on the intake side.

The verdict: probably a warped timing side case. BTW, the cases and main caps all have the same 4 digit number.

What do you recommend? Is line-boring the cams bearings on a t-150 big job, and can any machine shop do it?

Thanks Grandpaul, I appreciate you sharing your knowledge and experience.

PS- this list seems much less trafficed than a few years ago. Is that my imagination?

Well, I have been out of the business since 2013, so that might have something to do with slow traffic; I don't have much time for the forums any longer.

Any good machine shop should be able to replace the cam bearings (I would only replace the tight ones), and line bore them.

Any good machine shop should be able to replace the cam bearings (I would only replace the tight ones), and line bore them.

Similar threads

- Replies

- 117

- Views

- 17K